Molds Making Services for Short-Run & Mass Parts Production

2fprototypes Mold Types

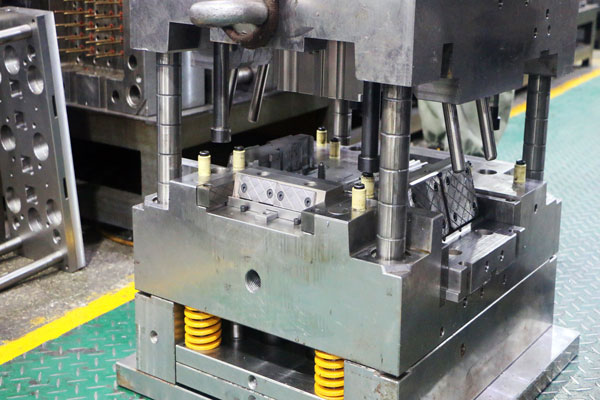

2fprototypes is capable to provide our customers with diversified molds for tools for both plastic and metal parts manufacturing. With our internal die-making equipment and superior suppliers, our tool and die are made by CNC machining, sheet metal fabrication, and stamping. Whether you need rapid tooling for short-run production or dies for mass production, 2fprototypes is your smart choice.

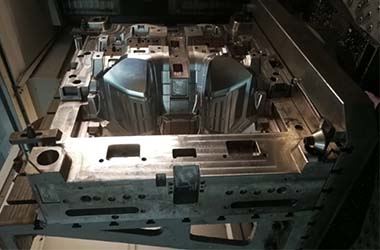

Plastic Injection Mold(PIM)

Plastic injection molds usually are made of aluminum or steel. They are used to make parts from glass-filled nylon, acrylic, silicone, etc. The application of plastic injection molds includes almost all industries from complicated automotive safety components to simple pen shell.

Capabilities For Die Making

A short video for mold making & injection molding process in our factory

Why Choose 2fprototypes' Mold Making Service

DFM (Designed for manufacturing) report

Failure is expensive. 2fprototypes provide a feasibility review when providing the quote and DFM after order confirmation. Any possible issues are included in the DFM report. We concern about what you are concerned about.

One-stop die-making services avoid project splitting

One-stop means faster accomplishment. 2fprototypes offer wide options of mold materials and the following injection molding.

Without MOQ

To make our mold-making services affordable at any scale, 2fprototypes never requires a minimum quantity and dollar value.

Cost advantage

In our experience, Local companies is more expensive than China companies. China has more cost-effective choices of labor and materials. 2fprototypes could lower your project cost by our intensive resources.

Experience and Strength

Cooperation with a reliable company is the first choice of every customer. 2fprototypes has been working silently in mold customization and production for 12 years and has received numerous large and small mold orders, accumulating strong mold design, manufacturing and production capabilities.

Try 2fprototypes Now

All information will be secured and confidential