- Home

- CNC Machining Service

Precision CNC Machining Metal & Plastic Part

CNC Machining Services

Welcome to manufacture quality parts for your project with us. 2fprototypes is a leading global manufacturer of CNC machining, manufacturing complex and tight tolerance metal and plastic prototype parts through CNC milling, CNC turning, CNC drilling advanced technologies.

Why choose 2fprototypes as your partner?

✔ 145+ sets of 3/4/5-axis CNC machining centers capacity

✔ Tolerances down to 0.003mm-0.005mm

✔ Quality inspection by Height Dial, YVM and CMM advanced equipment

✔ A variety of surface treament processes

✔ Within 24h quick interactive quotes

✔ Self-owned factory Fast turn around time

✔ Pass certification ISO9001:2005. ISO13485:2016. IATF16949:2016

✔ Designated supplier of Fortune 500 companies

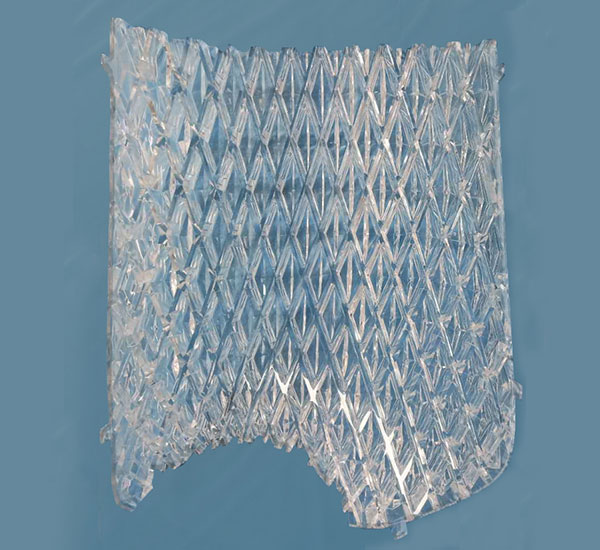

CNC Machined Parts Display

2fprototypes is capable to meet customers’ needs of quantity on-demand. Alongside our quick turnaround, we provide CNC machining service in low, medium, and large quantities. Our machined parts are serve across wide industries: automotive, medical devices, electric appliance, hardware startups, machinery automation , robotics, etc. 2fprototypes have various CNC machines to be responsible for tolerance, shape, and structure. That means our customers could save their headaches of quantity when considering CNC machined prototypes and small batch of CNC parts.

Our CNC Machining Capabilities

2fprototypes is proud to offer kinds of CNC machining services with different specifications. You will definitely find the right machining method for your CNC machined prototypes or custom parts in 2fprototypes.

| General Machining Information | |||||

| 3-Axis Milling | 3+2-Axis Milling | 4-Axis Milling | 5-Axis Milling | Turning | |

| Max Processing Strokes | 2600 x 2600 mm 102.4 x 102.4 in |

1000 x 650 x 600 mm 39.4 x 25.6 x 23.6 in |

850 x 550 x 600 mm 33.5 x 21.7 x 23.6 in |

660 x 1020 x 500 mm 26 x 40.2 x 19.7 in |

860 x 300 mm 33.9 x 11.8 in |

| Precision | ±0.015mm | ±0.015mm | ±0.015mm | 0.003mm-0.005mm | ±0.01mm |

| Max Speed | 15,000 | 20,000 | 20,000 | 24,000 | 4,500 |

HSM (high speed machining) is a recent advance in machining technology of fast and lighter cutting. High speed machining is usually identified as above 15,000 rpm or multi-axis CNC equipment that can perform nearly all operations. 2fprototypes owns several 4-axis and 5-axis CNC machines. With RPM from 15,000 to 24,000, we can meet your high speed machining needs.

The Advantages of CNC Machining

Professional And Various Surface Finish Treatments

⭐ Spray painting

⭐ Silk-screen

⭐ Transfer-printing

⭐ Electroplating

⭐ Laser etching

⭐ Anodizing

⭐ Scouring/brushing

⭐ High glaze

⭐ UV-finish

⭐ Embossing

⭐ Polishing

⭐ Cleaning

⭐ Bake finish

⭐ Fuming PC

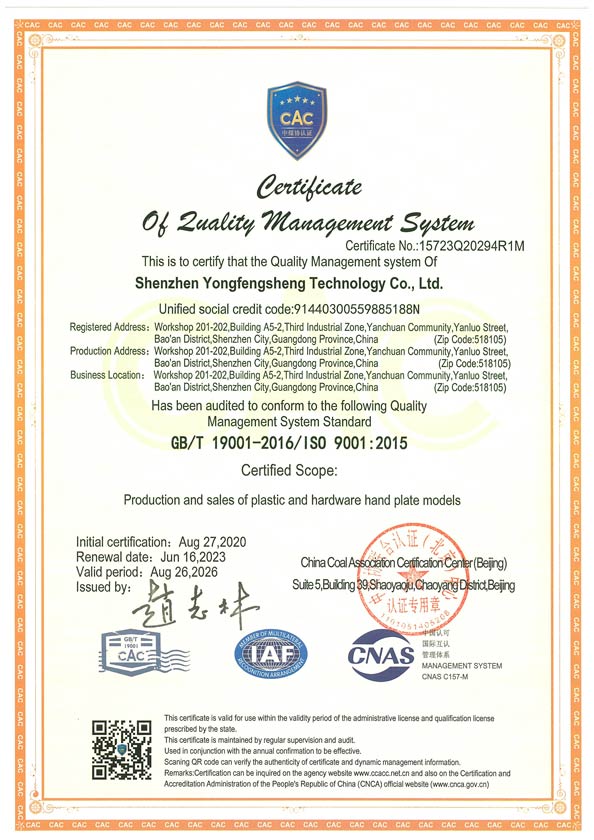

Our Certifications

2fprototypes have pass certifications of ISO 9001, IATF 16949, ISO 13485: 2016, ISO/IEC 27001 to guarantee our customers’ products quality and information security.

Our Working Process

Try 2fprototypes Now

All information will be secured and confidential