Sheet Metal Stamping - Flourish Forever Technology Co., Ltd.

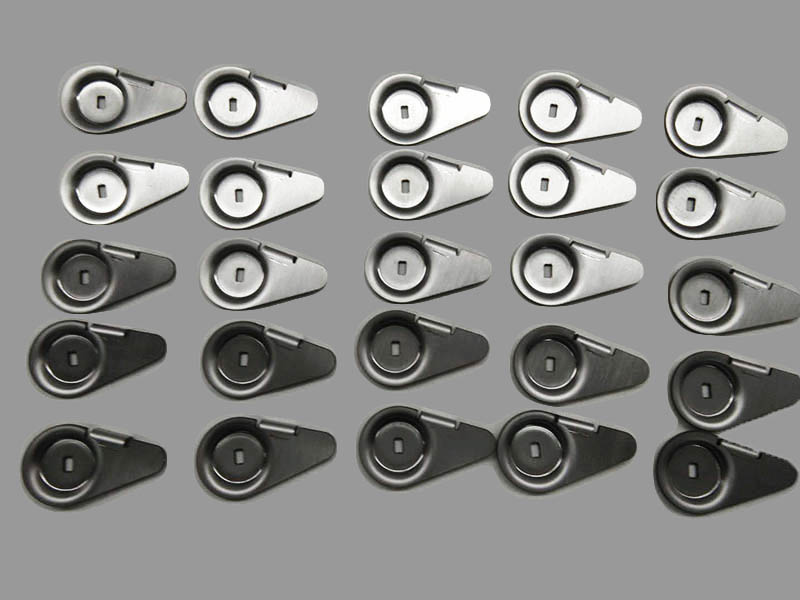

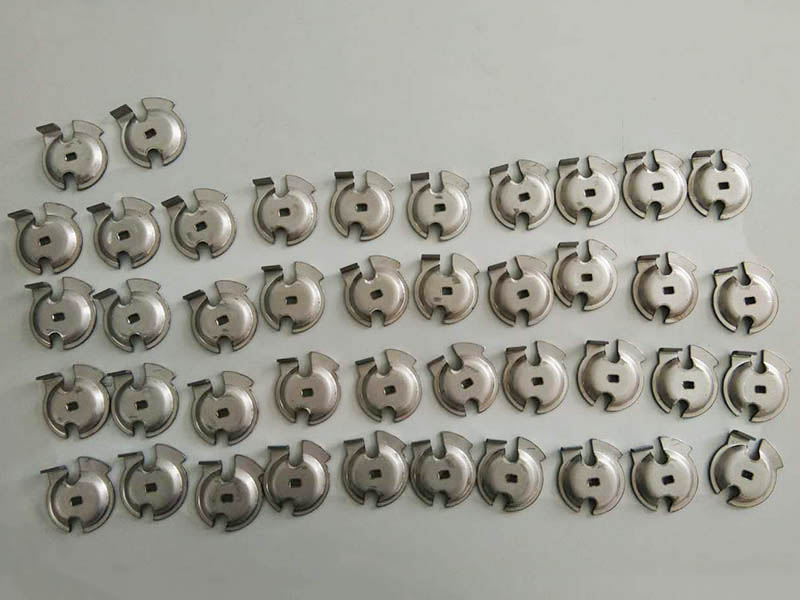

Metal Stamping Service

Why Choose 2fpototypes As your Metal Parts Stamping Manufacturer

2fprototypes' Stamping Capabilities

The diversity of metal stamping equipment can meet lots of needs in size, materials, thickness, etc.

Every press of the stamping machine goes through elastic deformation as the material has resistance to being deformed, the stamping must conquer the resistance and other forces.The maximum tonnage that a press can withstand without compromising any of its components is called press tonnage capacity. 2fprototypes’ stamping equipments cover ranges from 25 ton to 120 ton of presses.

Material List for Metal Stamping

Metal material of stamping requires enough strength to support the finished products while remaining flexible for fluent geometry shape. Depending on the desired property of the finished parts, the metal used in stamping is usually in hardness grade from soft to medium. The common stamping metal type includes:

Ferrous metal

Iron-based alloy such as stainless steel. Ferrous metal is in low carbon content that they are the least expensive choice among stamping metals.

Precious metal

Gold, silver, platinum, etc.

Non-ferrous metal

Metals that do not contain iron such as bronze, brass, zinc, etc.

Non-standard alloy

Beryllium nickel, beryllium copper, etc.

2fprototypes work with a wide range of sheet metal stamping materials. Contact us if your preferred material is not on the below list.

- Stainless steel

- Aluminum

- Brass

- Cold-rolled steel

- Hot-rolled steel

- Galvanized

- Other metal alloys

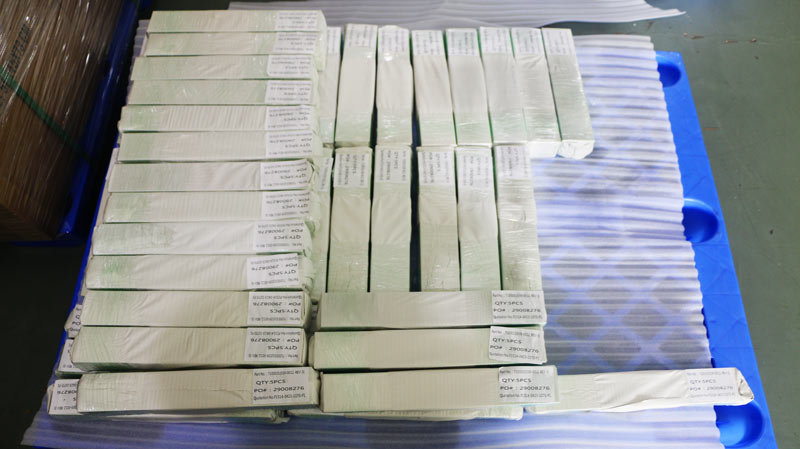

Advantages of Choosing Stamping Process for Metal Parts

Low cost die

Precision and auto stamping machines

Environmentally friendly technology

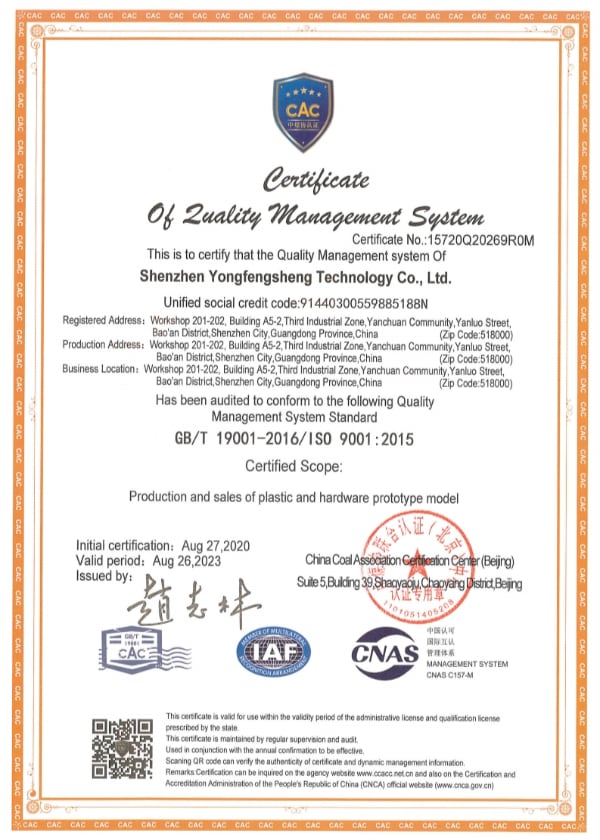

ISO Certified

2fprototypes have pass certifications of ISO 9001, IATF 16949, ISO/IEC 27001 to guarantee our customer’s information security and parts quality.

ISO 9001: 2015

ISO 9001: 2015 is The internationally recognized standard for Quality Management Systems (QMS). it is for all industry.

IATF 16949: 2016

A common automotive quality system requirement based on ISO 9001. It requires specifically to the automotive industry.

ISO/IEC 27001: 2013

Security standard that outlines the suggested requirements for building, monitoring and improving an information security management system.

Try 2fprototypes Now

All information will be secured and confidential