Advanced Machining Technologies and Challenges for Complex-Shaped Components

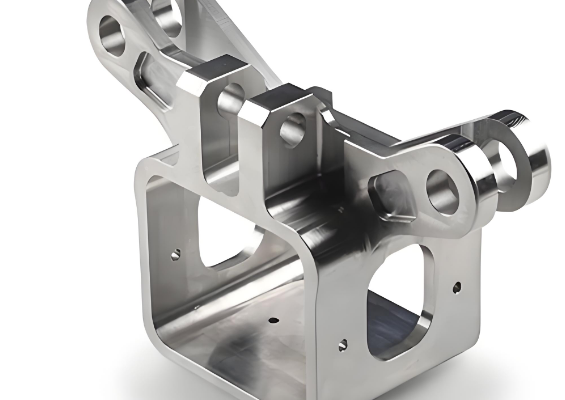

Complex-shaped components refer to parts with intricate geometries, tight dimensional tolerances, and high machining difficulty. These components are widely used in aerospace, automotive, medical equipment, and precision instrumentation industries. Due to their complexity, machining such parts requires advanced technologies, precision equipment, and extensive experience. This article explores the major challenges, technical approaches, and future trends in the machining of complex components.

I. Key Challenges in Machining Complex Components

1. Intricate Geometries:

Complex parts often feature challenging 3D shapes that traditional machining methods struggle to handle. Examples include turbine blades, gear systems, and aerospace engine components, which usually require multi-axis simultaneous machining capabilities.

2. High Precision Requirements:

Many complex components demand extremely high dimensional accuracy and tight geometric tolerances. Even the smallest deviation can cause performance failure, making precision and consistency absolutely critical during production.

3. Difficult-to-Machine Materials:

These components are often made from high-strength, heat-resistant, or corrosion-resistant materials, such as titanium alloys, superalloys, and composites. Their hardness and low thermal conductivity add to the machining challenges.

4. High Cost and Long Lead Time:

Due to their complexity, machining complex components typically involves advanced equipment and sophisticated processes, resulting in higher costs and longer production cycles. This places significant pressure on both efficiency and cost control.

II. Core Technologies for Machining Complex Components

1. CNC Machining:

CNC (Computer Numerical Control) technology is fundamental to machining complex parts. 5-axis CNC machines can produce intricate 3D forms with exceptional accuracy, making them widely used for complex component manufacturing.

2. EDM (Electrical Discharge Machining):

EDM removes material through electrical discharges and is particularly useful for hard materials and intricate shapes. It excels in mold making and micro-hole machining, where traditional cutting tools may not be effective.

3. Laser Machining:

Laser processing techniques such as cutting, welding, and drilling offer high precision with minimal heat-affected zones, making them ideal for micro-scale or complex structures.

4. Additive Manufacturing (3D Printing):

3D printing enables direct fabrication of complex shapes, especially for small-batch and rapid prototyping. Metal additive manufacturing is increasingly used in aerospace and medical applications.

5. Ultra-Precision Machining:

Technologies like ultra-precision turning, grinding, and polishing can achieve sub-micron or even nanometer-level precision, ideal for high-end optical and precision mechanical components.

III. Quality Control in Complex Part Machining

1. Precision Metrology:

Advanced measuring instruments such as CMM (Coordinate Measuring Machines), laser interferometers, and optical microscopes are used to verify dimensional accuracy and ensure consistency.

2. Non-Destructive Testing (NDT):

Techniques like X-ray, ultrasonic, magnetic particle, and fluorescent penetrant testing detect internal and surface defects without damaging the part, ensuring reliability and quality.

3. Process Control and Optimization:

Real-time monitoring of equipment status and machining parameters helps optimize cutting paths and processing parameters. Using AI and big data analytics further enhances process efficiency and accuracy.

IV. Future Trends

1. Smart Manufacturing:

With the advancement of Industry 4.0, smart manufacturing is becoming increasingly prevalent. IoT and data analytics enable interconnected machines, real-time data sharing, and optimized workflow control.

2. Multi-Material Hybrid Processing:

Combining different processing technologies allows the production of composite components with enhanced properties and extended service life, becoming a key direction for future development.

3. Green Manufacturing:

Future technologies will focus more on environmental sustainability and resource efficiency. By optimizing processes and material usage, manufacturers aim to reduce energy consumption and waste output.

4. Virtual Simulation and Digital Twin:

Simulating machining processes digitally helps identify issues before production. Digital twin technology enhances process transparency and control by synchronizing real-world operations with virtual models.

Conclusion

Machining complex-shaped components remains a major challenge in modern manufacturing, demanding advanced technologies, precision equipment, and skilled expertise. As new materials, smart systems, and innovative processes emerge, the machining of complex parts will continue to evolve—driving improvements in productivity, product quality, and industry competitiveness. Looking ahead, digitalization and intelligent manufacturing will unlock broader possibilities, enabling higher performance and precision across critical industries.