How to Communicate Efficiently with a CNC Machining Engineer?

Efficient communication with a CNC machining engineer is key to ensuring smooth part machining and the successful completion of manufacturing tasks. Here are some suggestions and steps to help you communicate effectively with the engineer before machining begins:

I. Preparation Phase

1. Detailed Drawings and Specifications

-

Provide complete part drawings, including all necessary views, dimensions, tolerances, and surface finish requirements.

-

Share 3D models of the part (if available) to help the engineer better understand the geometry.

2. Material and Quantity

-

Clearly specify the material to be used, including type, grade, and any special requirements.

-

Indicate the quantity of parts to be machined and the delivery timeline.

3. Function and Application Background

-

Explain the part’s function and its application scenario. This helps the engineer identify critical dimensions and tolerance requirements.

II. Communication Phase

1. Initial Meeting

-

Conduct an initial meeting (online or offline) to discuss the overall machining requirements.

-

Confirm that the engineer fully understands the drawings and specifications.

2. Technical Discussion

-

Dive into machining steps, equipment selection, fixture and tooling design, etc.

-

Discuss potential challenges, such as material properties, complex geometries, and tight tolerances.

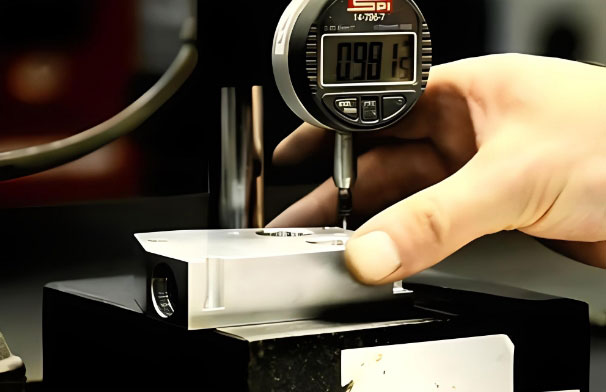

3. Quality Control Requirements

-

Clarify quality requirements, including how key dimensions will be measured, inspection tools used, and inspection frequency.

-

Talk through quality assurance processes and any critical checkpoints.

4. Machining Lead Time and Schedule

-

Confirm the machining timeline and discuss milestone delivery dates.

-

Clarify the procedures for expedited production if urgent issues arise.

III. Production Phase

1. Sample Production and Approval

-

Perform sample machining before mass production to confirm that the output meets specifications.

-

Address any issues discovered during sample production and adjust the process before scaling up.

2. Production Monitoring

-

Regularly track production progress and quality, and address any issues promptly.

-

Maintain close communication with the CNC machining engineer to ensure smooth operations.

3. Problem Solving and Continuous Improvement

-

Handle any production issues in a timely manner, making adjustments and improvements as necessary.

-

Summarize the machining experience to optimize future workflows and processes.