Why Injection Molding Remains a Smart Choice in Modern Manufacturing

In today’s fast-paced manufacturing landscape, where efficiency, cost-effectiveness, and precision are more important than ever, injection molding continues to stand out as a smart and reliable production method. Whether for producing automotive parts, medical devices, consumer electronics, or household goods, the versatility and scalability of injection molding make it indispensable.

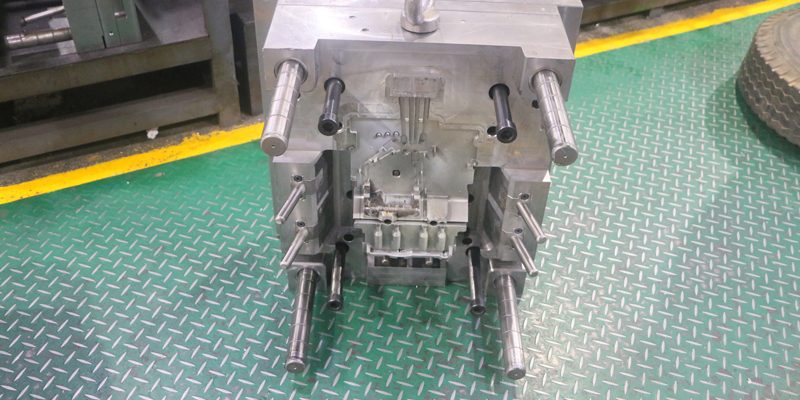

(1)At its core, injection molding is about consistency and control. Once the mold is created, thousands—even millions—of identical parts can be produced with minimal variation. This not only reduces waste but also lowers per-unit costs dramatically, which is especially critical in mass production.

(2)Another key benefit is material flexibility. From robust engineering plastics to biodegradable options, injection molding supports a wide range of materials, helping manufacturers meet diverse performance and sustainability needs.

(3)Moreover, the process is constantly evolving. With the integration of AI, robotics, and real-time monitoring systems, modern injection molding shops are becoming smarter and more energy-efficient, delivering higher precision while reducing turnaround time.

As a company with 17 years of experience in CNC and plastic injection manufacturing, we’ve seen firsthand how innovation keeps this industry moving forward. The future of injection molding isn’t just about making parts—it’s about making better, smarter, and more sustainable parts.

If you’re looking for a trusted partner in injection molding who values quality, service, and long-term collaboration, we’re here to help.