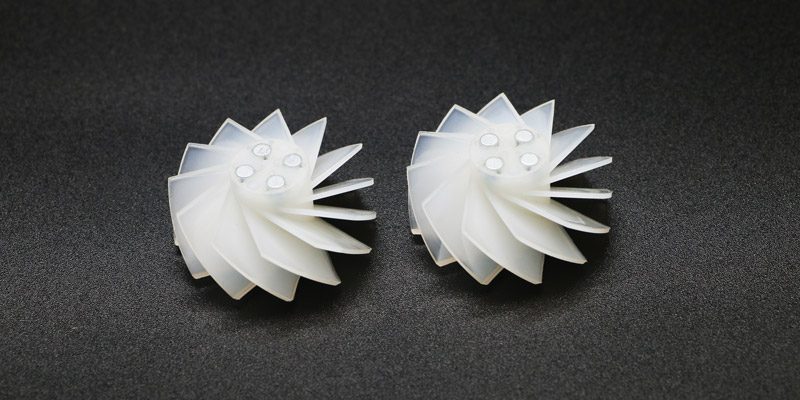

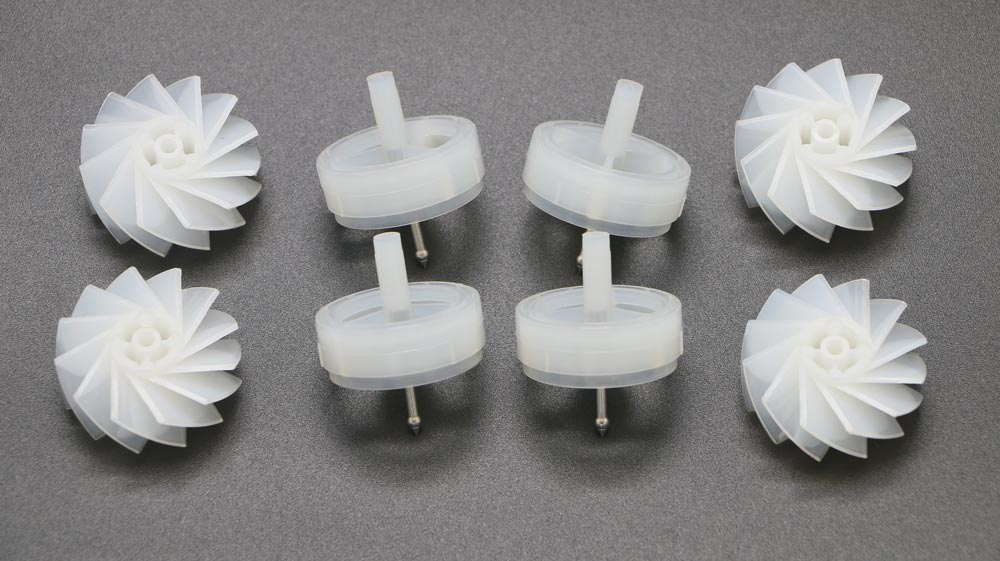

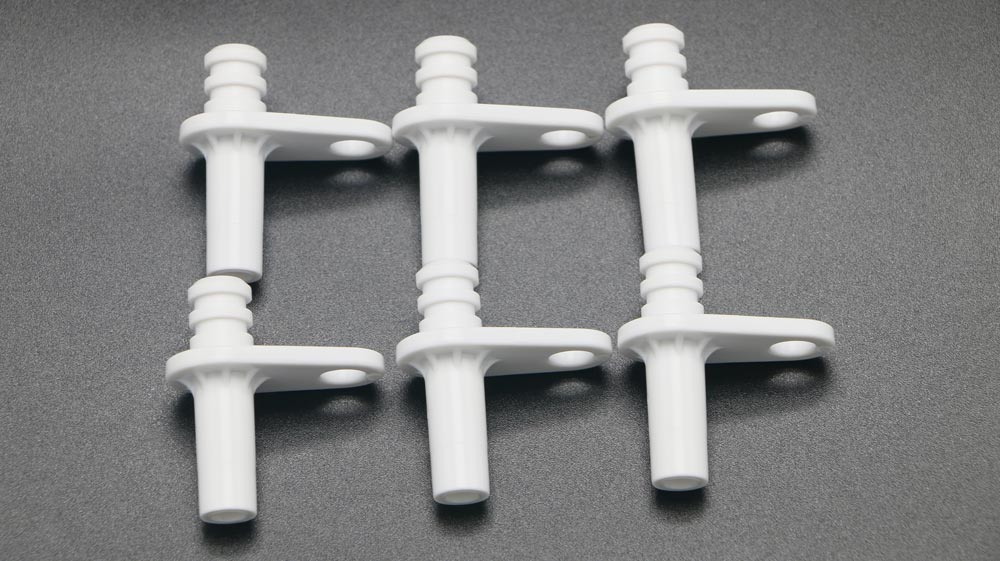

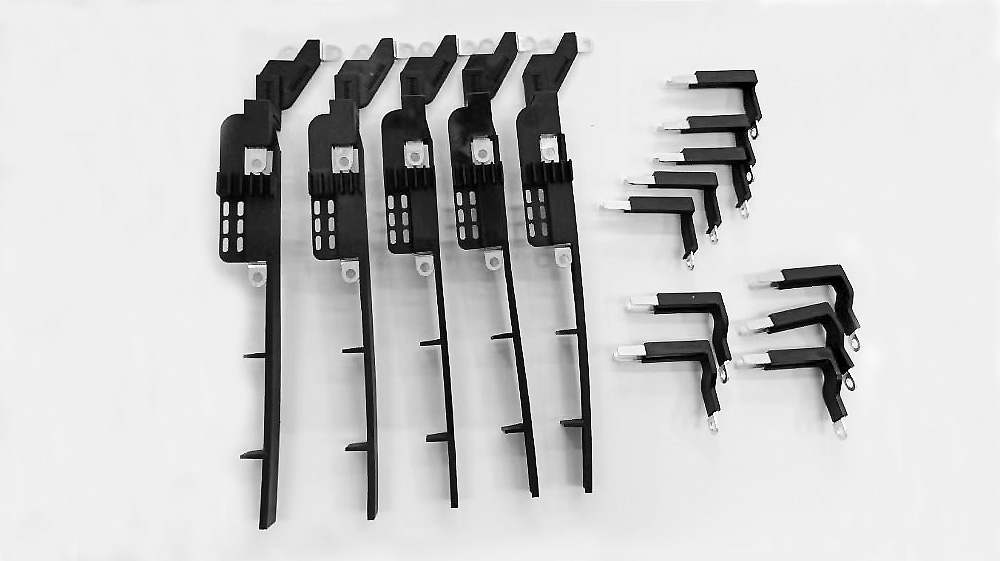

Plastic Injection Molding

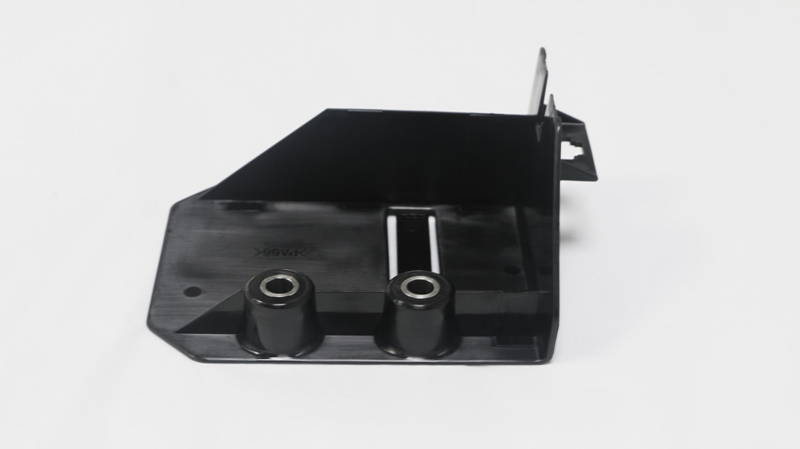

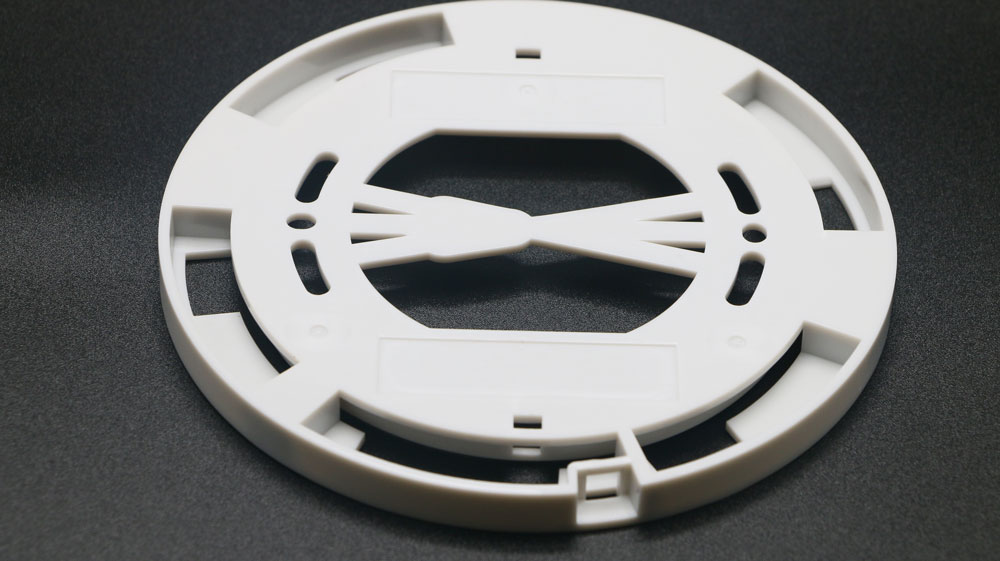

In our daily life, we see all kinds of plastic products, such as advertising signs, casings of electronic products, casings of cosmetics, etc. You may be curious about how it is made, and these plastic parts are consumables. As long as human civilization exists, there will be a market for plastic parts. Have you ever been moved by this opportunity that can bring wealth? Back to the topic, in fact, these plastic products we see are composed of various semi-finished parts. When it comes to plastic parts, people first think of injection molding. To be precise, these semi-finished plastic parts are obtained through an injection molding process.

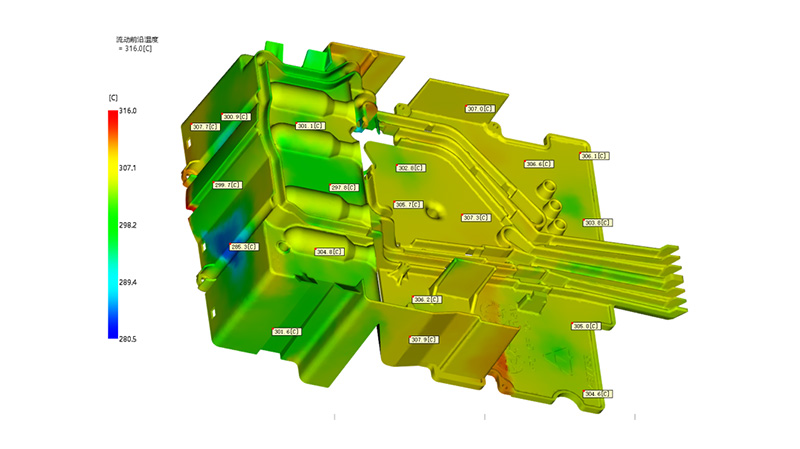

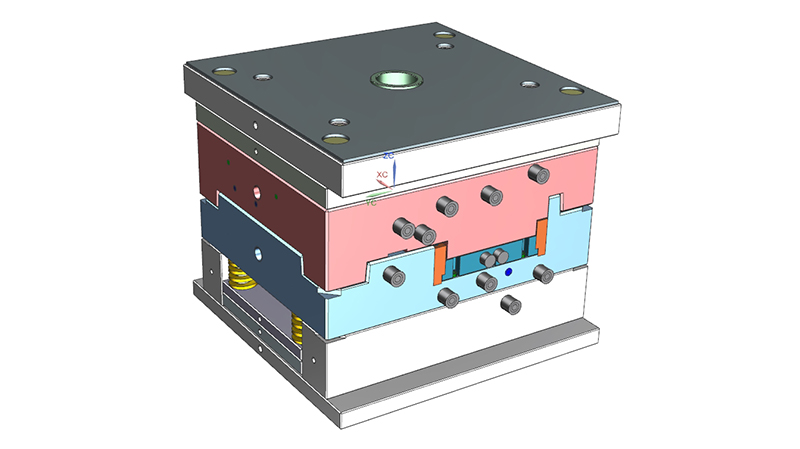

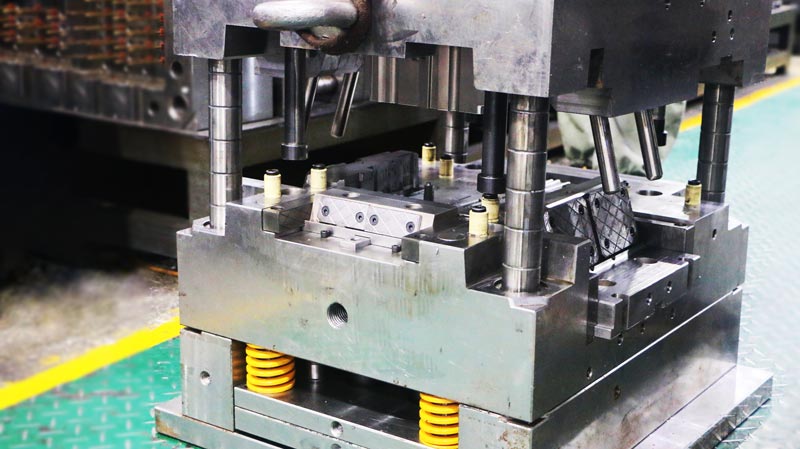

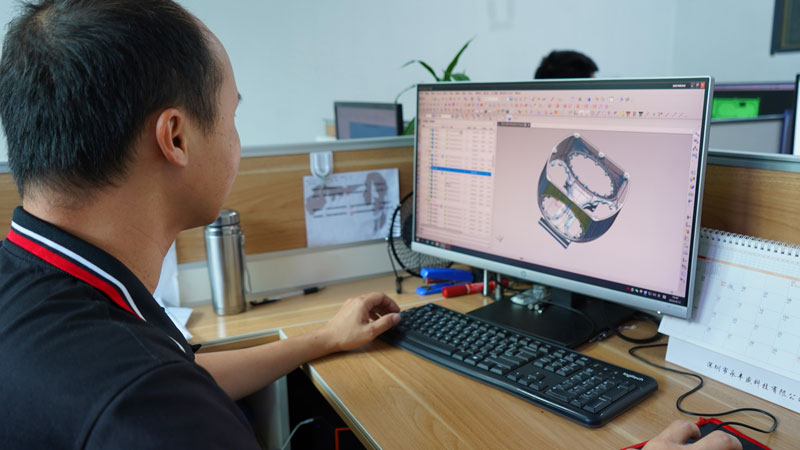

The injection molding process is the first choice for mass production of plastic parts because of its repeatability, wide range of material options, low labor costs, high precision and little need for complex post-processing steps.

You may also be curious about the raw materials for making various semi-finished parts. 2fprototypes summarizes that the following materials are basically used in the plastic injection molding process :

ABS (Acrylonitrile Butadiene Styrene)

Acetal (Delrin)

Acrylic

Rigid PVc

Soft PVC

Peek (Polyetheretherketone)

Liquid Crystal Polymer

Long-Fiber Reinforced Plastics

Nylon (PA)

Polyurethane (PU)

Polycarbonate (Pc)

Polyester (PET)

Polyethylene (PE)

Polyphenylene Sulfide (PPs)

Polypropylene (PP)

Polystyrene (Ps)

Polybutylene Terephthalate (PBT)

Polyetherimide (PEI) – Ultem

Thermoplastic Elastomer (TPE)

PolysulfoneNoryl(PPO + PS)

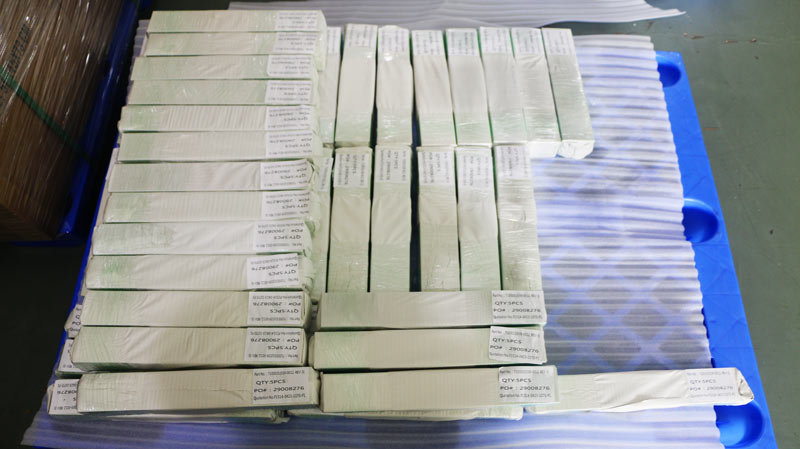

If you are also curious how much does it cost to make 1 injection molded part or 1000 injection molded parts. Welcome to consult 2fprototypes – an original manufacturer specializing in injection molding. Click here to get an instant quote.